Reposting from one of the Springfield FB Groups:

Scott Folk is at Apex Tactical Specialties, Inc.

· 1m · Peoria, AZ ·

Hey guys, I posted this in a few of the Hellcat groups a little while ago and thought I'd share it here as well.

In our product development process at Apex, we test the crap out of new products. Often times we come up with weird tests that push the product well past anything that an end user would ever do. In doing so, we learn a lot about how our decisions effect the final product.

The common material of choice for most aftermarket products is aluminum because it's fast to machine, relatively cheap and can be anodized multiple colors to meet the "Gucci Factor" requests that are always present.

In this case, I'm specifically referring to the Extended Mag Release for the Springfield Hellcat Series Pistols. We looked at aluminum but rejected it at the outset due to the mating surface on the factory mags being stainless steel.

The contact points between components are the most critical to consider for durability. If you have a polymer mag body use of a polymer or aluminum mag release is perfectly fine, Glock is a good example of this. A steel mag release won't generally hurt the poly mags, but it may be overkill for the job.

At the "Project Approval" Phase of any product, we establish testing parameters for the engineers to design the product to meet or exceed. The parameters we established for all of our Magazine Releases is as follows:

Desired Life Span: 10 years

Most detrimental Mag Drop: Fully loaded mag with the slide in battery (This provides the most force on the magazine release at drop)

Unloading Conditions: Once Daily for the life span (3650 drops)

Safety Factor: 2x (3650 x 2 = 7300). Round up for additional margin to 10,000.

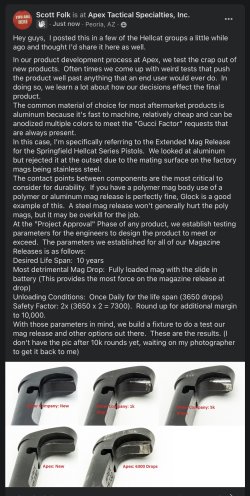

With those parameters in mind, we build a fixture to do a test our mag release and other options out there. These are the results. (I don't have the pic after 10k rounds yet, waiting on my photographer to get it back to me)