I like the BUL products a lot and will probably add the SASII UL eventually. Good review of the 4.25 from Honest Outlaw, who offers his thoughts on this and the Prodigy.

Good reviewer , just to vulgar to listen to all the time . It gets old .

I like the BUL products a lot and will probably add the SASII UL eventually. Good review of the 4.25 from Honest Outlaw, who offers his thoughts on this and the Prodigy.

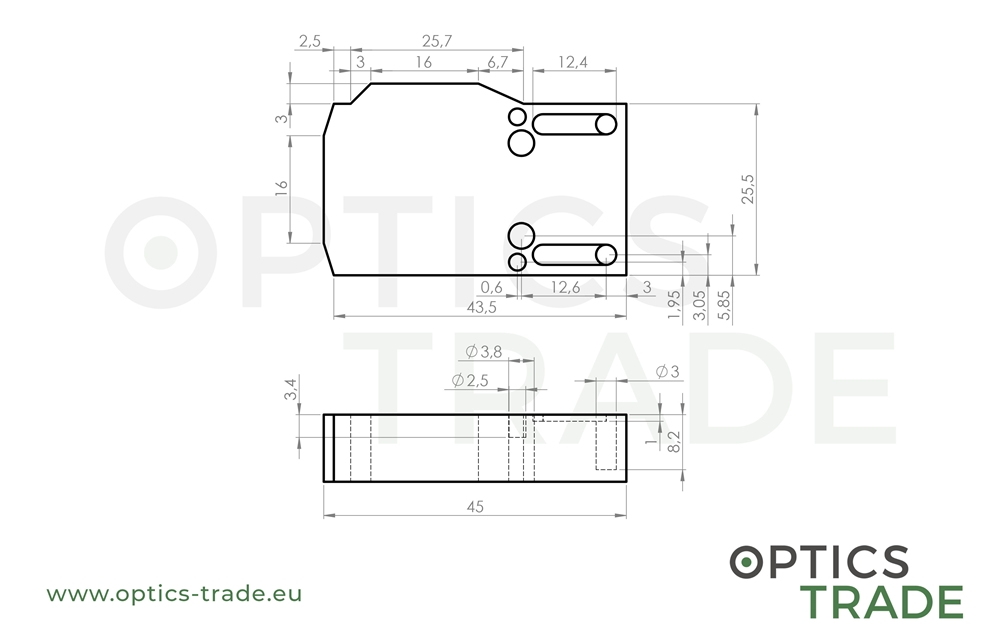

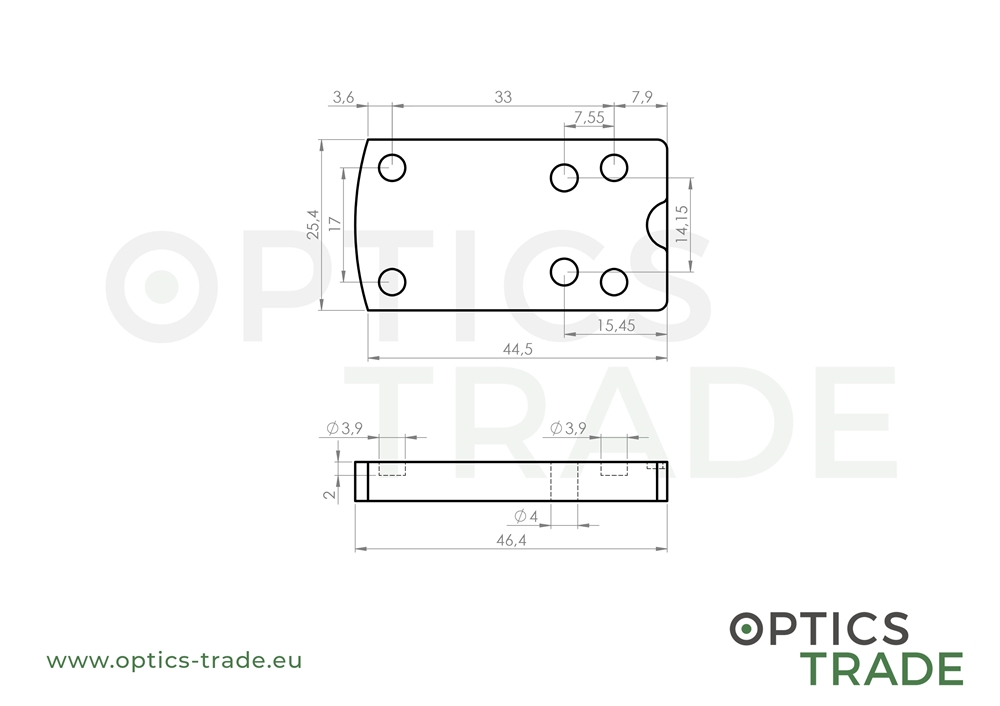

Yeah something doesn't add up thereGot my plate for the DPP which has the same footprint as the Rome 1 Pro I had waiting to install. Unfortunately the lug pattern is different. ARRRGGHHH. There is no way to even file them smaller to fit. I am going to give the plate folks a call. If there is nothing coming or they can't make something, I will likely just file off the posts and make some type of shim system front or back as needed. Have also considered drilling the plate and using pins or drilling, tapping and using set screws as posts.

So the mounting holes to the plate match, it is just the lugs on the plate that do not.

www.optics-trade.eu

www.optics-trade.eu

www.optics-trade.eu

www.optics-trade.eu

I’m running a DPP on mine. It’s definitely the way to go. I had the same problem with the Romeo 1 Pro. The DPP and R1P both fit my X5 Legion and M17, but not the Prodigy.That sucks Sol… I know on my Sig 320s, the Romeo1 pro and DPP both work, same footprint.

I know I have the plate that is for Vortex Venom or Viper as well as HS 407c.

I can tell you the viper didn’t fit… I had to file down the front to get it to work…and then I never had enough vertical adjustment. I went 407c and haven’t looked back.

I do really, really like the DPP on my Legion X5. let us know how this works out…there’s a possibility I may go DPP on my Prodigy one day.

Hear ya. At this point, although I do like the DPP better, I’m gonna spend the funds on ignition for my Prodigy instead of optic. Time to clean up the trigger action on it… I think I’m somewhere in the neighborhood of 1K rounds since back from SA and it just keeps ticking.I’m running a DPP on mine. It’s definitely the way to go. I had the same problem with the Romeo 1 Pro. The DPP and R1P both fit my X5 Legion and M17, but not the Prodigy.

Good job -But u shouldn't have to do it .I just decided to grind and then file down the studs this morning. Had to use the shroud or would have had too file off a thread or two. We will see how it holds. Will get to the range tomorrow.View attachment 35266View attachment 35267View attachment 35268

You doing the ignition yourself ? Atlas has devoted a series on Youtube for the Prodigy specifically . Good stuffHear ya. At this point, although I do like the DPP better, I’m gonna spend the funds on ignition for my Prodigy instead of optic. Time to clean up the trigger action on it… I think I’m somewhere in the neighborhood of 1K rounds since back from SA and it just keeps ticking.

I gotta be honest, I’m 50/50. I’ve always done all my own drop in kit work on my striker fired guns, my M&P, Glocks and now all my P320s.You doing the ignition yourself ? Atlas has devoted a series on Youtube for the Prodigy specifically . Good stuff

You should be fine. Watch a few videos. Don't worry about replacing or polishing any parts. The MIM will get even smoother and they are surface hardened and I don't like to mess with very thin hardened layers. Just the simple bending of the sear spring leafs will get you a long way. Do not buy into all the hype that you need to pay someone hundreds of dollars or replace a bunch of perfectly good parts.I gotta be honest, I’m 50/50. I’ve always done all my own drop in kit work on my striker fired guns, my M&P, Glocks and now all my P320s.

But this is my first 1911 style…and as simple as they may seem to the experienced shooter and user, they’re a little intimidating to me.

When kits are sold as “not 100% drop in” and some gunsmithing may be required, I have the tools, of course. The knowledge and understanding from experience I do not.

I may have caught a little of the Atlas stuff, so it sounds like I have more vids to watch…. Thanks Rick.

Thanks Sol… kinda what I was hoping to hear. I’d like to get a little less pre-travel, less overtravel and lighten it up a few lbs. Currently over 5… like to settle in mid 3#. If that all can be done with the simple bending of the springs…perfect.You should be fine. Watch a few videos. Don't worry about replacing or polishing any parts. The MIM will get even smoother and they are surface hardened and I don't like to mess with very thin hardened layers. Just the simple bending of the sear spring leafs will get you a long way. Do not buy into all the hype that you need to pay someone hundreds of dollars or replace a bunch of perfectly good parts.