How to Make a Kydex Holster

January 23rd, 2024

7 minute read

There is satisfaction in creating a project or completing a job. Whether it is re-plumbing a bathroom, installing an engine or tending a garden, something is innately human about putting our minds and hands to a task. I made a custom holster for my Springfield Armory Hellcat and it was a thoroughly pleasing project.

My avocation has been making knives. But you can’t just build a knife; the blade has to have a sheath for its safe carry. I tried my hand at leatherwork. I’m not so good there, but still working at it. A material I did learn to apprentice with is thermoplastic sheet. Known as Kydex, Boltaron, Holstex, or other trade names, these are plastics that can be easily heat-formed into sheaths or holsters.

Getting Started with Kydex

Since I had never made a gun holster before, and I love a challenge, my mission was to make an Armory Life-themed custom holster for my Hellcat. I received permission from my esteemed editors (somewhere in an Ivory Tower mired in the clay of an outdoor firearms range, I suppose) to use The Armory Life logo for my project. I opened a freeware graphics program and went to work on the design.

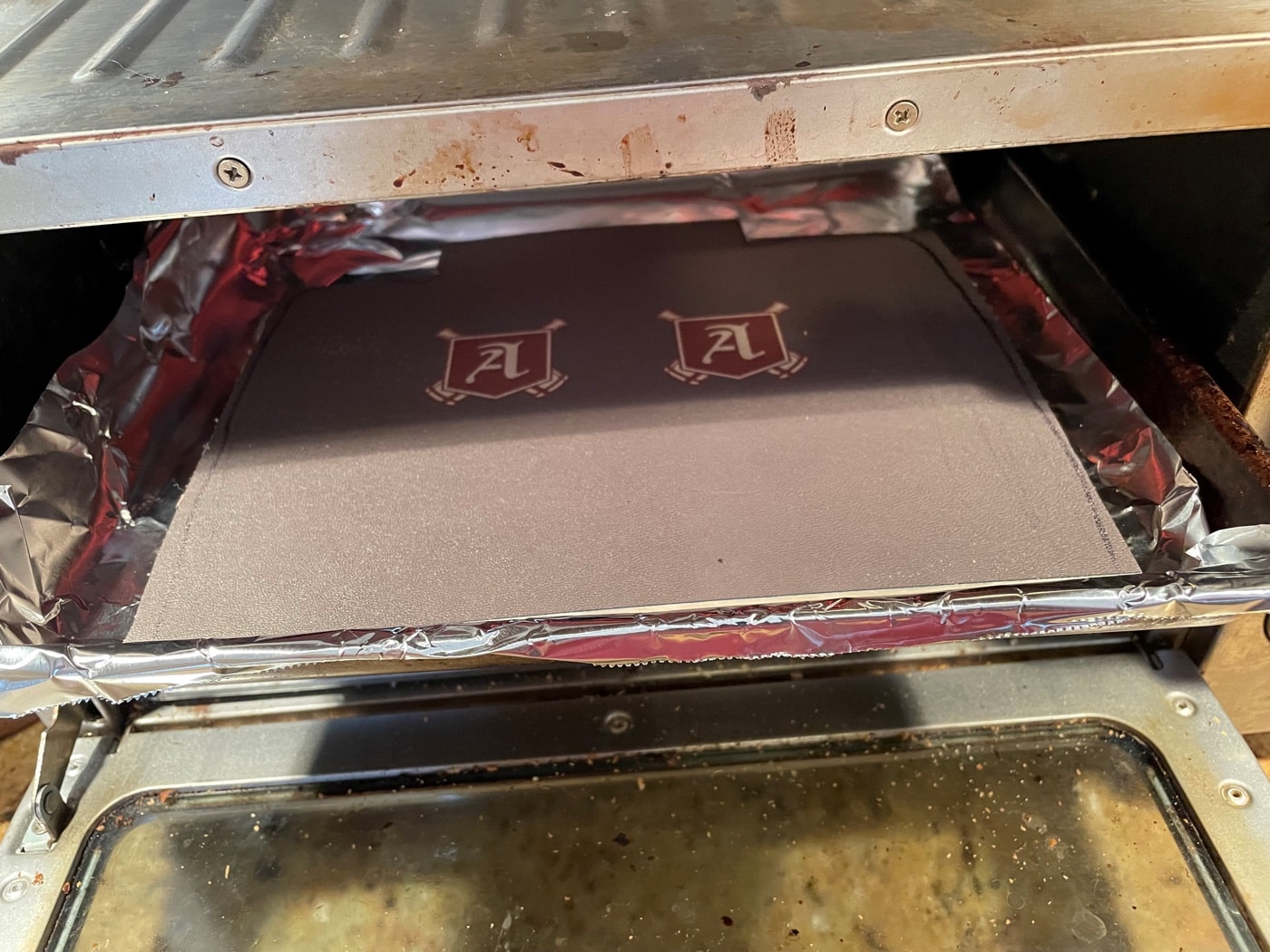

Thermoplastics can be purchased in many colors, patterns, and textures. They may also be infused with custom images. After shopping a few companies, I eagerly collaborated with Dan Wichers at Tacticalinfusions.com. Dan was very helpful in assisting me with the resolution of my graphics and the color of the base Kydex sheet that would complement the lighter parts of the logo. Once I completed the designs, I emailed them to Tactical Infusions.

I ordered four sheets, in two different designs, and several additional holster-making parts. When the custom sheets arrived, I was thrilled with how they turned out. The details of TAL logo were crisp and the hues perfect. Dan’s customer service was outstanding, and I will use him for future projects, whether gun or knife related. A single-color 12” x 12” sheet of Kydex in .080” thickness cost $6.25. I paid about 11 bucks for each custom sheet of Kydex from Tactical Infusions. This was friendly to my wallet.

Ready to Make a Kydex Holster

Making a holster begins with preparation. I could have used my Hellcat to make the holster. The heat of thermoforming is much less than that generated when firing the gun. But I had previously purchased a Ring’s Blue Gun Hellcat replica for tactical practice, so I used that instead. I taped a dowel rod on the top of the pistol’s slide. This created a channel so the front sight does not hang up on the plastic when drawing the gun.

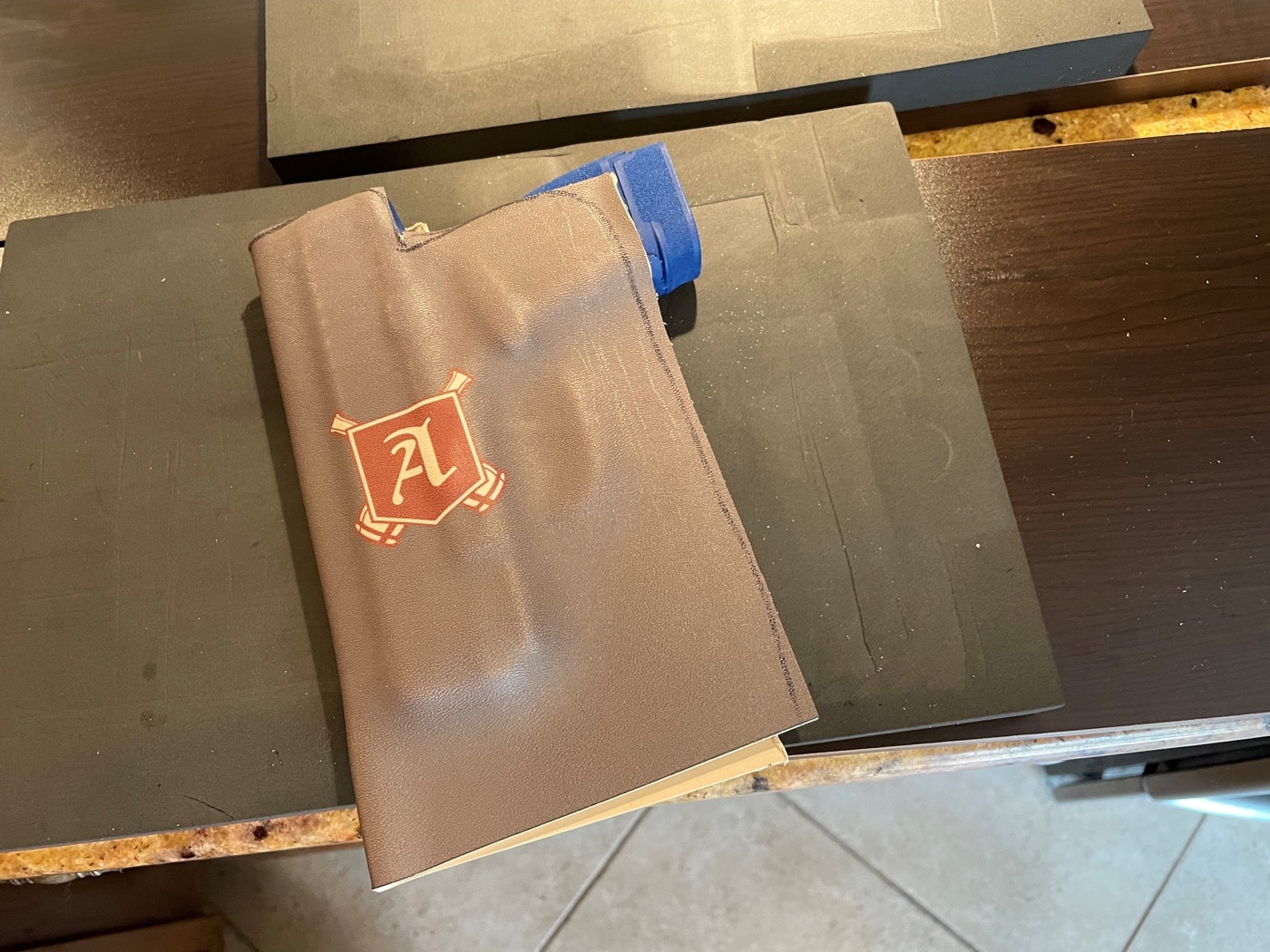

Next, I sketched an initial layout of the holster on the inside of the Kydex. I was making what’s called a “taco sheath” for the Hellcat. This is a single piece of thermoplastic folded over like your favorite South-of-the-Border handheld snack. The preliminary outline was very rough since I would be trimming off the unneeded portions later.

These thermoplastics can be heated in a full-sized oven or smaller toaster oven. I used the latter with the Kydex placed on a small baking sheet. Aluminum foil sat between the Kydex and the baking sheet because I don’t want the missus getting annoyed with me again. The oven should be set between 330 and 400 degrees, but not any higher. Thermoplastics will burn when too hot.

To get an even forming over the gun, I have two pieces of closed cell foam intended for this purpose. While you may use a handheld infrared thermometer to check the degrees, I manually judged the temperature of the Kydex. It becomes very pliable when manipulated with tongs so you will know when it is ready to go. If you see the edges begin to curl, it is on the verge of burning. Get it out of there!

When the Kydex has reached the necessary temperature, place it on one piece of the foam, land the gun where you want it, fold the Kydex tightly over, and sandwich the other foam on top. Gloves help. Time is of the essence, so get them pressed together quickly. You need a decent amount of pressure to get the right impressions of the gun’s surface into the Kydex. I used two thick wooden cutting boards and clamps. The Kydex will stay hot inside the foam halves, so let the entire affair stay compressed for at least fifteen minutes to cool.

There are commercial presses available for holster-forming. Some are very nice indeed. Other DIY folks make their jigs by gluing the foam to boards and building their hinges and clamps. I do not make many sheathes and so my low-tech methods are sufficient for me. The most important point is to buy foam made to withstand the high heat used in this procedure.

When the blank has been formed and is room temp, the shape of the holster can be outlined and the excess trimmed away. I used a tabletop bandsaw for this. To keep the sides even, I employed a bench grinder on the edges before taking out sandpaper for finishing. I started hand sanding at 220 grit and ended with 400 grit. Nothing fancy here in the deburring and shaping. At the very least, and I’m sorry I have to say this, make sure your homemade holster covers the entire trigger guard of the firearm.

My Armory Life holster was made with inside-the-waistband (IWB) carry in mind. I left enough Kydex material in front of the trigger guard to drill holes for a carry clip. The clip was also thermoplastic. I mounted it using blackened hardware and color-matched brown washers. With the two holes in the holster body, I can also bolt a small upward-facing plastic hook so the rig can do double duty as a pocket carry holster. I like the versatility.

In addition to the taco design, a two-piece Kydex sandwiched holster is also infinitely useful. These are best utilized for outside-the-belt carry because they result in plastic on either side of the gun to mount clips or loops. The Kydex can also be radiused to fit your torso.

Final Thoughts on Making Your Own Carry Rig

This process can be repeated to make knife sheaths and holsters for pens, flashlights, and all manner of tools. You can construct carriers for your “toys” that match your homemade pistol holster. There is a dizzying array of colors and designs from which you to choose. Let the internet catalogs fuel your creative fire.

I am thrilled to carry my Springfield Armory Hellcat in the custom The Armory Life holster that I conceived and built with my ingenuity. It is handmade and one-of-a-kind. While my skill level in the workshop might be average, my pride of ownership is well above that!

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!

Join the Discussion

Featured in this article

Continue Reading

Did you enjoy this article?

211

211