When you hear the name Nightforce, what is the first thought that comes to your mind? For me, it is the legendary nature of the brand and the fact their products are used by US Special Operations. As I reflect on the success of Nightforce, I can’t help but ponder how they achieved such a place of quality and renown among professionals. There are plenty of fantastic precision optics manufacturers around the world — and everyone claims to be the best — so how can you really tell?

On Site

I had the honor of spending a couple days at the Nightforce headquarters in Orofino, Idaho, touring the facility and getting to speak to people like Ray Dennis, the founder of the company. Getting such a deep and detailed look into the operation and history of Nightforce left me with a profound respect for the people and the products of the company.

Starting at the top, the motto and mantra of Nightforce Optics are the three R’s: Rugged, Reliable, Repeatable. Ray Dennis takes that a step further and says the employees are also rugged, reliable, and repeatable, adding a P for passionate. I’ve toured many production facilities, and I can confidently agree with Ray’s assessment of the workforce at Nightforce Optics. Everyone that we encountered was obsessed with creating the best products for the end-user, period.

Let me take you through some of the processes that a scope goes through as it is manufactured and assembled at the Nightforce Facility.

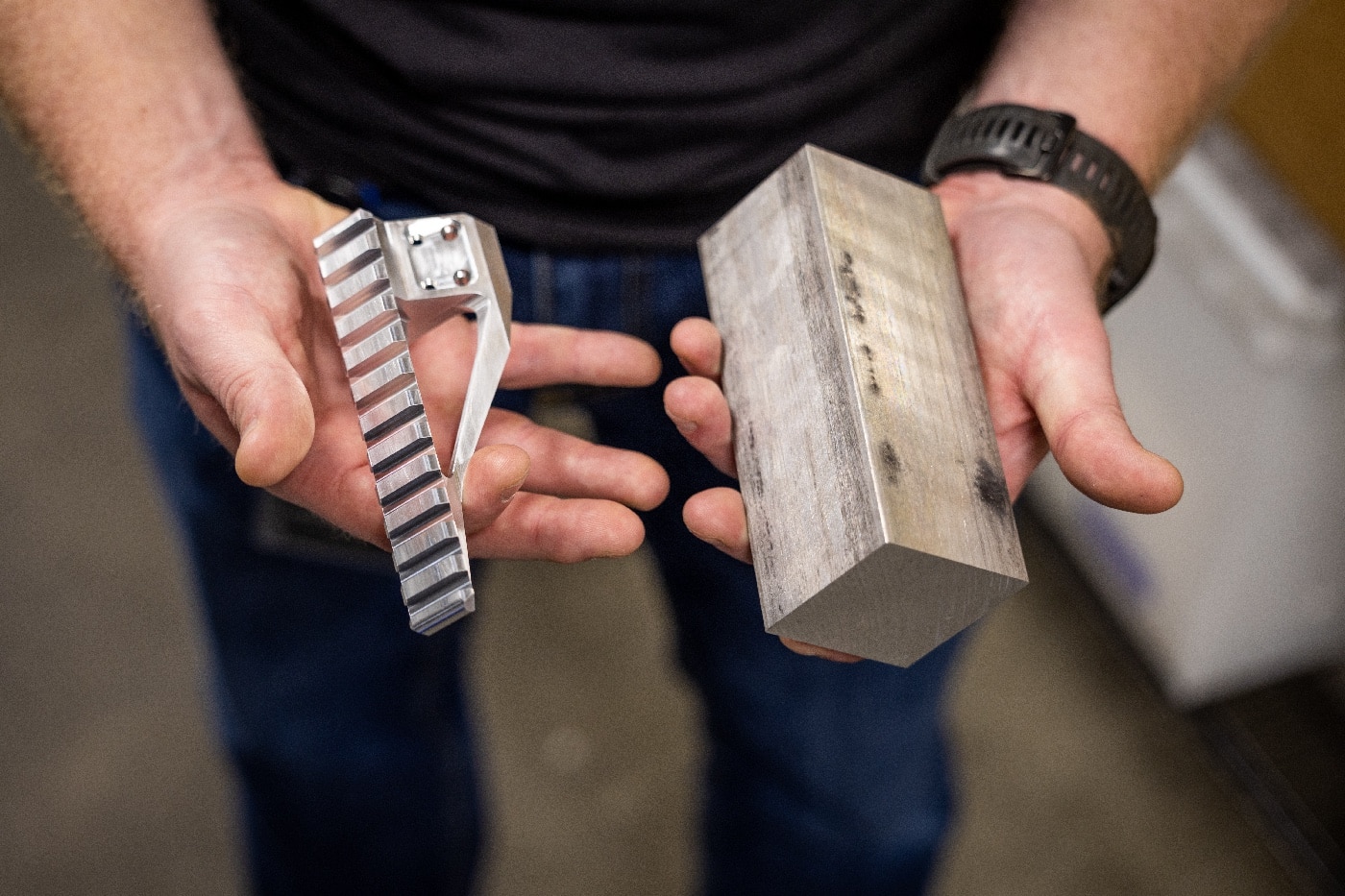

In the machine shop, the team was busy using the finest materials and machines to create the housings, turrets, and other pieces of the ATACR and NX8 line of optics. The QC department was inspecting the finest ED glass for anything less than perfection, and the assembly team was putting everything together with great care and attention to detail.

The one aspect that totally blew me away was one of the final tests that almost every Nightforce optic goes through before it goes out the door.

On one of the last stations in assembly there sits a technician with a machine that projects a reticle onto a plane that houses an optic. The optic is checked to see if the reticles line up together perfectly. To the right of that technician is a steel post with a rubber top. Once the reticle is aligned and confirmed as zeroed, the tech then begins to bang the optic multiple times on the post. They then check to see if the reticle is still aligned.

They repeat this process on all four sides as well as the front and rear of the scope. Once the scope has passed every impact while still retaining zero, it gets the Nightforce stamp of approval with the initials of the technician, showing that the product met the Nightforce standard. During the entire process, the scopes are inspected and checked at 70-130 different points, depending on the model.

Talk about putting your money where your mouth is. After seeing their brutally detailed QC process, I was ready to swipe my credit card on a new ATACR 4-20x50mm.

When developing a new scope, optics are tested in a pressure tank to simulate 100 feet of water for 24 hours. The scope is then frozen to -80°F and then heated to 160°F within a one-hour period. Every lens in every scope is matched and aligned by hand, yielding the highest levels of optical performance.

Nightforce scope tubes are made from solid bar stock 6061-T6 aluminum that is two to three times thicker than most other riflescopes, which allows greater thermal stability, consistent zero, and overall, less stress on the internals.

The Nightforce team even takes the spring that maintains pressure on their elevation and windage adjustments and puts it in a polishing tumbler for two weeks before it going into a Nightforce scope. These little details make a Nightforce one of the best scopes in the world.

The Options

If you are new to the Nightforce line-up, here is a breakdown of the families Nightforce offers.

The ATACR line is their premium offering created for military and law enforcement professionals. If you want a professional, no-expense-spared optic that will perform to perfection, the ATACR line is for you.

The NX8 line is the evolution of the NXS riflescopes, which has been proven for over two decades in the hands of the military, law enforcement, hunters and competitive shooters. The NX8 line boasts an 8X zoom range that is sharp at every setting. This is achieved by using premium materials and the latest optical technology.

The SHV line is the most affordable product that Nightforce offers, giving the shooter quality at a reasonable cost.

The NXS line are workhorses that have been building the Nightforce reputation for decades and keep on performing.

Finally, the Competition and Benchrest riflescopes are built for the specific needs of those user groups, ensuring precision reliability that champions demand.

The Foundation

With such a sterling reputation and world-class products, you might be surprised by Nightforce’s humble beginnings. It all started when Ray Dennis was a young boy in the Australian outback hunting at night with his grandfather.

In Australia, rabbits, foxes and pigs are considered varmints that can wreak havoc on a landowner’s crops. Therefore, the best time to hunt these creatures was when they were most active, at night. Ray’s grandfather would rig up large lights to the rifles with automotive batteries connected to a belt so that they could see at further distances with clarity.

As Ray got older, he realized there wasn’t a great light or optic built for his night hunting needs. He began development on a rifle light that could spot animals out to 400 yards. At the 1986 Shot Show where he was showing his lights under the Lightforce brand, he found a Japanese optics manufacturer that could create a scope based on his requests. He ordered 500 scopes, and they were a huge success.

The U.S. market reacted poorly to the spotlights since night hunting was not something participated in here, but the scopes were a big hit. The company then set up a Seattle branch to focus on making scopes for the U.S. market. In 1990, the company was renamed Nightforce. Dennis now operates his lighting products under Lightforce, while the rifle optics remain under the name Nightforce.

In 1998, the company moved from Seattle to Orofino where they currently reside. Soon after, they began producing the NXS line of optics that, in 2010, won a contract with USSOCOM. Nightforce continues to provide the U.S. Military with optics that give our soldiers the edge in combat.

Conclusion

If you ever get the opportunity to peer through some legendary Nightforce glass, proceed with caution as you may not be able to go back to your old glass once you see what you have been missing. With Nightforce, you get exactly what you pay for — perfection.

Editor’s Note: Please be sure to check out The Armory Life Forum, where you can comment about our daily articles, as well as just talk guns and gear. Click the “Go To Forum Thread” link below to jump in and discuss this article and much more!

Join the Discussion

Featured in this video

Continue Reading

Did you enjoy this video?

50

50